Plunger Pump and Accessories

Pump

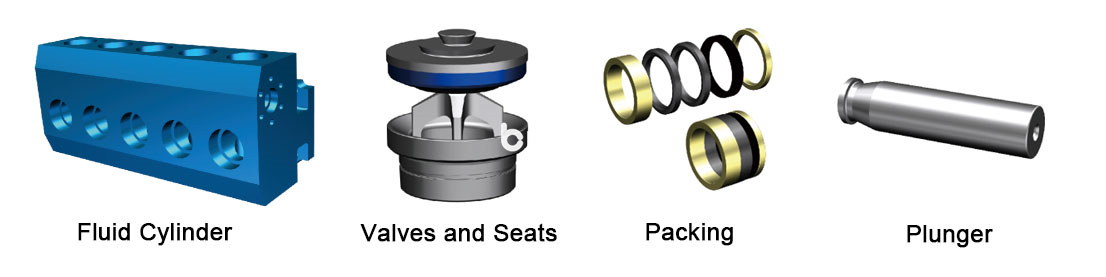

plunger pump, valve, packing, plunger

1. Plunger Pump

1.1 Structural

Electric reinjection pump skid, Mainly composed of frequency control asynchronous motor, Frequency conversion control system, Pressure monitoring system, Three-cylinder plunger pump, Coupling, Power end lubrication system, Packing lubrication system, Displacement monitoring system.

1.2 Working principle

The triplex plunger pump is connected with the AC variable frequency motor through the universal joint coupling, and converts the rotational energy of the AC variable frequency motor into the reciprocating motion of the plunger.

1.3 Electric drive pump features

a) The electric drive pump is controlled by frequency converter. The inverter has complete protection functions. It can realize over-voltage, over-current, low-voltage, phase loss, over-load, short-circuit and other faults. It can be automatically converted to power frequency operation to ensure the normal operation of the plunger pump.

b) The frequency converter has a communication function, which can realize remote concentration and facilitate the detection of equipment operation.

c) Frequency conversion starts to reduce the impact on the power grid, in line with the needs of the site.

d) The whole structure is simple and compact, and the floor space is small, which is easy to install and transfer.

e) It has no exhaust gas has excellent environmental protection characteristics.

1.4 Technical Data

| Rated power | 600HP |

| Max. load | 1000000lbf |

| Stroke length | 6” |

| Transmission ratio | 4.6:1 |

| Overall size | 57.48*53.23*27.24in |

| Weight | 16500lbs |

| Plunger Diameter | Displace | GALLONS PER MINUTE AT PUMP REVOLUTIONS PER MINUTE | |||||||||

| mm | L/Rev | 50 | 120 | 200 | 300 | 450 | |||||

| LPM | Mpa | LPM | Mpa | LPM | Mpa | LPM | Mpa | LPM | Mpa | ||

| 63.5 | 1.4 | 72 | 143.6 | 174 | 142.1 | 290 | 85.3 | 434 | 56.8 | 651 | 37.9 |

| 69.9 | 1.8 | 87 | 118.6 | 210 | 117.4 | 350 | 70.5 | 526 | 47 | 788 | 31.3 |

| 76.2 | 2.1 | 104 | 99.7 | 250 | 98.7 | 417 | 59.2 | 625 | 39.5 | 938 | 26.3 |

| 88.9 | 2.8 | 142 | 73.2 | 341 | 72.5 | 568 | 43.5 | 851 | 29 | 1277 | 19.3 |

| 101.6 | 3.7 | 185 | 56.1 | 445 | 55.5 | 741 | 33.3 | 1112 | 22.2 | 1668 | 14.8 |

| 114.3 | 4.7 | 235 | 44.3 | 563 | 43.9 | 938 | 26.3 | 1407 | 17.5 | 2111 | 11.7 |

| Brake Horsepower (kW) | 188 | 450 | 450 | 450 | 450 | ||||||

| Pinion RPM | 230 | 552 | 920 | 1380 | 2070 | ||||||

Based on 90% ME and 100% VE - Intermittent service only

2. Fluid End Assembly

400W

| Material | SAE 4330V | Stainless Steels | |||

| Plunger Diameter | 3.375'' | 4'' | 4.5'' | 5'' | 6'' |

| Stroke | 8'' | ||||

| Max. Pressure | 20000 | 14000 | 11200 | 9000 | 6250 |

| Compatibility | Compatible with popular power ends, eg. HB etc. | ||||

600S

| Material | SAE 4330V | Stainless Steels | ||||

| Plunger Diameter | 2.5'' | 2.75'' | 3'' | 3.5'' | 4'' | 4.5'' |

| Stroke | 6'' | |||||

| Max. Pressure | 20000 | 17200 | 14450 | 10615 | 8135 | 6420 |

| Compatibility | Compatible with popular power ends, eg. SPM/GD etc. | |||||

2500Q

| Material | SAE 4330V | Stainless Steels | |||

| Plunger Diameter | 3.5'' | 3.75'' | 4'' | 4.5'' | 5'' |

| Stroke | 8'' | ||||

| Max. Pressure | 20000 | 17415 | 15300 | 12090 | 9795 |

| Compatibility | Compatible with popular power ends, eg. OFM etc. | ||||

3. Plunger pump accessories

3.1 Fluid Cylinder

a) Optimized internal cavity structure reduces the stress concentration at the intersecting position and extends service life by 20%;

b) Adopting internal cavity strengthening process delays crack initiation and expansion, improves bearing capacity and fatigue resistance, and extends service life by nearly 40%;

c) Application of stainless steel material significantly reduces the corrosion impact, and the comprehensive performance indicators have also been significantly improved, extending service life by 3 ~10times.

3.2 Valves and Seats

a) Can endure 37% hydrochloric acid and adapt to - 30 ~ 110 ℃;

b) Improved anti-slip design increases movement resistance and improves service life;

c) Matching size is optimized to improve the reliability and stability of the seal;

d) Ultra-audio heat treatment process ensures sufficient strength and toughness.

3.3 Packing

a) Complete category can meet the needs of various applications such as high pressure and acid working conditions;

b) Composite seals are easy to maintain with full universality;

c) Customized solutions to meet different customer needs.

3.4 Plungers

a) Automatic spray welding technology improves quality stability;

b) Excellent surface finish can maximize the service life of accessories;

c) Head connection and chamfering design ensures reliable connection and easy to install and disassemble.