Poor Boy

Solid Control Equipment

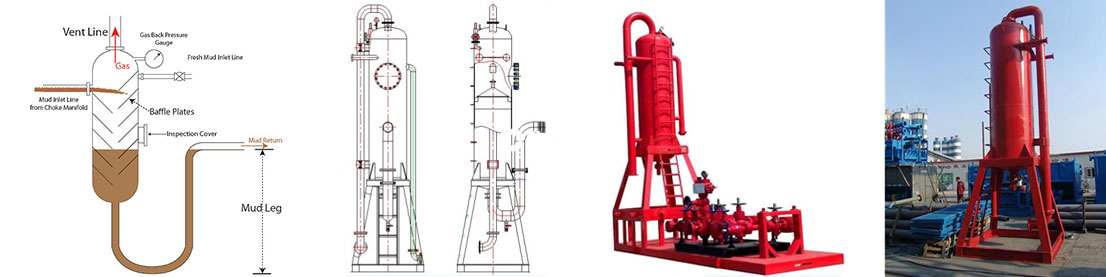

Mud Gas Seperator/ Poor Boy Degasser

Mud gas separator located at downstream of the choke manifold is one of the important well control equipment that you need to focus. It separates gas out of the mud after the gas comes out of hole. Gas will be vented to atmosphere via the vent line in derrick (offshore operation) or the line away from the rigs (land operation) and the mud will be returned back to the pit. In the oilfield, people have several names for the mud gas separator as “poor boy degasser” or “gas buster”. While drilling, the mud gas separator should be lined up at all times and filled with the present mud weight currently used.

Oilfield drilling Poor boy degasser that removes air or gases (methane, H2S, CO2 and others) from drilling liquids. There are two generic types that work by both expanding the size of the gas bubbles entrained in the mud (by pulling a vacuum on the mud) and by increasing the surface area available to the mud so that bubbles escape (through the use of various cascading baffle plates). If the gas content in the mud is high, a mud gas separator or “poor boy degasser” is used, because it has a higher capacity than standard degassers and routes the evolved gases away from the rig to a flaring area complete with an ignition source.

Working Principles

The concept of this equipment is density difference between liquid and gas. When the mud coming out from the choke manifold goes into the mud gas separator, mud will hit the baffle plates which are used to increase travelling time and allow gas to move out of the mud. Gas which has lower density than air will move up and mud will go down due to gravity. Mud leg will provide hydrostatic pressure in order to prevent mud going through the separator into the rig.

Features

●High performance based Oilfield drilling Poor boy degassers

●Assists in effectively removing air or gases from drilling liquids

●Made available in different functional capacities as per the specific process application needs

●Parameters can also be customized as demanded by the customers

●Simple structure with strong vibration deck for easy operation

●Composite frame screen for long working time and convenient replacement

●Patented embedded sealing technology to prevent fluids leakage

●Anti-corrosion epoxy coating to ensure long service life

●Mainly used to clear away big bubbles of Φ3-Φ25mm.

●Reducing hazardous gas threat: separated free gas is discharged by vent lines to a safe place for combustion.

●Adopting bottom-sealing structure

●Skid-Mounted

Technical Data

| Separator Model | ZYQ800 | ZYQ1000 | ZYQ1200 |

| Main body diameter | 800mm | 1000mm | 1200mm |

| Capacity | 180~260m3/h | 240~320m3/h | 260~380m3/h |

| Inlet pipe | 5" | 5" | 5" |

| Output pipe | 6" | 8" | 10" |

| Gas discharge pipe | 8" | 8" | 8" |

| Weight | 1600kg | 2000kg | 2000kg |

| Dimensions | 1900×1900×5700mm | 2000×2000×5860mm | 2200×2200×6634mm |